I’ve commented before about getting into 3D printing, and the only major change made since the last mention was adding a resin printer to the mix, not too long after we moved to Walkabout Estates Plus – this was largely because before, The Girlfriend and I shared an office, and my desk wasn’t near a window and printing resin has a distinct odor, which I had no decent way to ventilate. Now with my own office where I can dedicate more space and put the desks where I want, I finally made my move on a resin printer.

[Exposition, skip ahead if you already know or don’t care: Resin printing is significantly different from FDM/filament printing. A vat with a clear bottom holds the ultra-violet sensitive liquid resin, and underneath sits a UV LED the same size as the vat. A build plate lowers into the vat until it sits a fraction of a millimeter above the bottom, enough for a thin layer of resin, and the LED illuminates long enough to harden the resin into a solid layer, usually about .05 millimeters thick, which is pretty fine. The build plate lifts enough to allow more liquid resin to flow underneath, descends again to compress this layer to the desired thickness, and the LED illuminates again – in this manner, it builds a model an entire layer at a time. Or really, as many models as you can cram onto the build plate, because the print job is timed by layers/height, not volume like FDM printers, so you might as well use the time wisely.]

Now there are two main uses for 3D printers. The first is knickknacks, miniatures for gaming, and so on. But the second is functional parts and even tools; I pretty much split my efforts between these, and it’s the latter we’ll talk about today.

Two days ago, in opening the blinds in the bedroom, there was a crack and suddenly not only would the blinds not open/rotate, one side was drooping noticeably. Pulling down the entire unit, I discovered that two of the three tilter drums inside had literally shattered, and I wasn’t going to simply restring the blinds.

Examination of the parts that remained told me that I wasn’t going to glue those back together either, and in fact, the plastic used had aged badly, likely from exposure to sunlight for too long, and was more the consistency of dried frosting. Seriously.

That’s utter shit, and clearly the wrong kind of plastic to use in such situations – and I have no doubt the manufacturer knows this. Nor are replacement parts available, because I checked extensively.

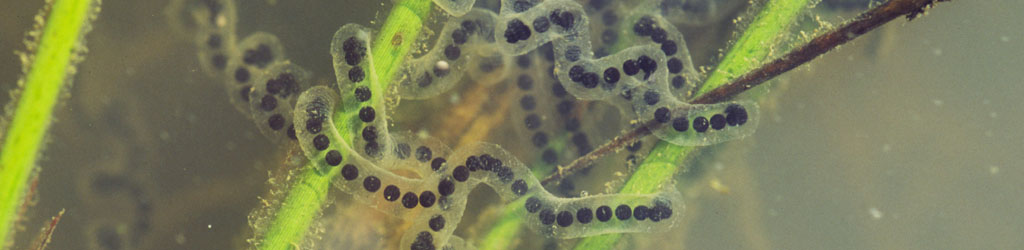

But, 3D printing to the rescue! A search on Thingiverse.com turned up (once I determined the name/term that I should be searching under) this home-designed part by Motard0067, which is exactly what I was looking for. I elected to use resin for the finished product, because it prints very cleanly and is a lot more durable than filament, just this side of ceramic. ABS in a filament machine would probably work too, and has more flexibility.

All three rotation drums were bad, so I did three resin drums, which are an absolute perfect fit, even threading on the rods snugly but not too tightly. A few minutes of playing around and the blinds were fixed, actually better than new.

The semi-clear bit on top is the locking tab from the original blinds, still intact and fitting properly in my printed parts – though I’m sure I could have found or designed replacements for those too.

I can’t count the number of times that I’ve fixed or improved items around the house, some of which could already be found on the popular 3D model sites, some of which I designed myself (and I’m certainly a novice at 3D design.) When the opportunity to print anything is there, you realize how often it can be a huge help.

I won’t recommend it to everyone – 3D printers can take a lot of tweaking to get the best prints, with a shit-ton of variables to account for, and if you’re not into troubleshooting or mucking about, you’ll hate it. Which is funny, because the basics are generally pretty easy, and most printers can be ready to operate within 20-60 minutes out of the box. But you can waste a couple of hours determining what temperature works best for what filament, and the setup, cleanup, and post-processing of resin prints is time-consuming and can be messy if you’re not meticulous.

But when you fix something that would otherwise have to be replaced (and I make it a point to try this for damn near everything,) well, what can I say? It pays for itself.

By the way, the long lens grip that I created many moons ago? It’s still in regular use, without even having to reprint it (despite the fact that it was created on my first, very basic printer,) and I consider it a huge advantage in wielding that lens.